Waterproof Coating

Coating Specifications

- 1. Exposed Type Urethane

- 2. Polyurea

- 3. Shingle waterproofing material

- 4. Inorganic ceramic waterproofing (interior waterproofing, bathroom, porch, balcony, underground waterproofing)

- 5. Sheet waterproofing material

- 6. Non-exposed waterproofing material

-

1. Exposed Type Urethane

1) 2K Elastic Urethane Waterproof (KS)

Category Painting Procedure Product Name Film Thickness Number of Coats Coating Method Color Remarks Concrete floor

Surface Treatment

Completely remove the laitance, dust, oil other foreign matter from the surface.

Primer

50㎛

1~2 times

B, R

Clear

Intermediate coating

3㎜

2 times

Rake, Scraper

Designated color

KS F 3211

(Eco Label)

Top coat

40㎛

1 time

B, R, S

Designated Color

2) 2K Elastic Urethane Waterproof (Non-KS)

Category Painting Procedure Product Name Film Thickness Number of Coats Coating Method Color Remarks Concrete floor

Surface Treatment

Completely remove the laitance, dust, oil other foreign matter from the surface.

Primer

50㎛

1~2 times

B, R

Clear

Intermediate coating

3㎜

2 times

Rake, Scraper

Designated color

Top coat

40㎛

1 time

B, R, S

Designated Color

3) 2K Elastic Urethane Waterproof (Non-KS)

Category Painting Procedure Product Name Film Thickness Number of Coats Coating Method Color Remarks Concrete floor

Surface Treatment

Completely remove the laitance, dust, oil other foreign matter from the surface.

Primer

50㎛

1~2 times

B, R

Clear

Intermediate coating

3㎜

2 times

Rake, Scraper

Designated color

Top coat

40㎛

1 time

B, R, S

Designated Color

4) 2K Elastic Urethane Waterproof (vertical wall coating)

Category Painting Procedure Product Name Film Thickness Number of Coats Coating Method Color Remarks Concrete floor

Surface Treatment

Completely remove the laitance, dust, oil other foreign matter from the surface.

Primer

50㎛

1~2 times

B, R

Clear

Intermediate coating

3㎜

2 times

Rake, Scraper

Designated color

Top coat

40㎛

1 time

B, R, S

Designated Color

5) 2K Elastic Urethane Waterproof (for energy saving)

Category Painting Procedure Product Name Film Thickness Number of Coats Coating Method Color Remarks Concrete floor

Surface Treatment

Completely remove the laitance, dust, oil other foreign matter from the surface.

Primer

50㎛

1~2 times

B, R

Clear

Intermediate coating

3㎜

2 times

Rake, Scraper

Designated color

KS F 3211

Top coat

40㎛

1 time

B, R, S

Designated Color

6) 1K Elastic Urethane Waterproof

Category Painting Procedure Product Name Film Thickness Number of Coats Coating Method Color Remarks Concrete floor

Surface Treatment

Completely remove the laitance, dust, oil other foreign matter from the surface.

Primer

50㎛

1~2 times

B, R

Clear

Intermediate coating

3㎜

2~3 times

Rake, Scraper

Green, Gray

KS F 3211

Top coat

40㎛

1 time

B, R, S

Designated Color

7) 1K Elastic Urethane Waterproof (for vertical surface)

Category Painting Procedure Product Name Film Thickness Number of Coats Coating Method Color Remarks Concrete floor

Surface Treatment

Completely remove the laitance, dust, oil other foreign matter from the surface.

Primer

50㎛

1~2 times

B, R

Clear

Intermediate coating

3㎜

2~3 times

Rake, Scraper

Green

Top coat

40㎛

1 time

B, R, S

Designated Color

8) Water-based Waterproof

Category Painting Procedure Product Name Film Thickness Number of Coats Coating Method Color Remarks Concrete floor

Surface Treatment

Completely remove the laitance, dust, oil other foreign matter from the surface.

Primer

CLEANPOXY PRIMER

50㎛

1~2 times

B, R

Clear

Top coat

1㎜

4 times

B, R

Black, Green, Gray

-

2. Polyurea

1) Waterproofing for rooftops, concrete parking lots

Category Painting Procedure Product Name Film Thickness Number of Coats Coating Method Color Remarks Concrete floor

Surface Treatment

Completely remove the laitance, dust, oil other foreign matter from the surface.

Primer

50㎛

1~2 times

B, R

Clear

Intermediate

coating 1

1㎜

1 time

Rake, Scraper

Designated color

Intermediate

coating 2

2~3㎜

2~3 times

Equipment for polyurea

Designated color

Top coat

40㎛

1 time

B, R

Designated Color

2) Steel parking lots

Category Painting Procedure Product Name Film Thickness Number of Coats Coating Method Color Remarks Concrete floor

Surface Treatment

Completely remove the laitance, dust, oil other foreign matter from the surface.

Primer

PROTECH 130

50㎛

1 time

B, R

Designated color

Intermediate coating

2~3㎜

2~3 times

Equipment for polyurea

Designated color

Top coat

40㎛

1 time

B, R, S

Designated Color

-

3. Shingle waterproofing material

Category Painting Procedure Product Name Film Thickness Number of Coats Coating Method Color Remarks Concrete floor

Surface Treatment

Completely remove the laitance, dust, oil other foreign matter from the surface.

Primer

NEW WATERPOXY PRIMER

50㎛

1~2 times

B, R

Clear, Semitransparent

If necessary

Intermediate/Top coat

1000㎛

2 times

B, R

Green, Reddish brown

-

4. Inorganic ceramic waterproofing (interior waterproofing, bathroom, porch, balcony, underground waterproofing)

Category Painting Procedure Product Name Film Thickness Number of Coats Coating Method Color Remarks Concrete floor

Surface Treatment

Completely remove the laitance, dust, oil other foreign matter from the surface.

Primer

WELLPOXY PRIMER/

50㎛

1~2 times

B, R, S

Clear

Intermediate coating

1.5㎜

2 times

Rake, Scraper

Designated color

Top coat

40㎛

1 time

B, R, S

Designated Color

-

5. Sheet Waterproofing Material

1) Concrete surface

Category Painting Procedure Product Name Film Thickness Number of Coats Coating Method Color Remarks Concrete floor

Surface Treatment

Substrate treatment is not necessary.

Protector

PE foam

5~10㎜

1 time

White

Top coat

1.2 or 1.6㎜

1 time

Hot blast welding

Gray

2) Panel surface

Category Painting Procedure Product Name Film Thickness Number of Coats Coating Method Color Remarks Concrete floor

Surface Treatment

Substrate treatment is not necessary.

Insulation board

PR board

50㎜

White

Protector

PE foam

5~10㎜

White

Top coat

1.2 or 1.6㎜

Hot blast welding

Gray

-

6. Non-exposed Waterproofing Material

1) Complex Method

Category Painting Procedure Product Name Film Thickness Number of Coats Coating Method Color Remarks Concrete floor

Surface Treatment

Completely remove the laitance, dust, oil other foreign matter from the surface.

Primer

50㎛

1~2 times

B, R

Clear

Intermediate coating

1㎜

1 time

Rake, Scraper

Black

Top coat

1.5㎜

1 time

Blue

2) Elastic Urethane (2K)

Category Painting Procedure Product Name Film Thickness Number of Coats Coating Method Color Remarks Concrete floor

Surface Treatment

Completely remove the laitance, dust, oil other foreign matter from the surface.

Primer

50㎛

1~2 times

B, R

Clear

Intermediate coating

3㎜

2 times

Rake, Scraper, R

Black, Green, Gray

3) Elastic Urethane (1K)

Category Painting Procedure Product Name Film Thickness Number of Coats Coating Method Color Remarks Concrete floor

Surface Treatment

Completely remove the laitance, dust, oil other foreign matter from the surface.

Primer

50㎛

1~2 times

B, R

Clear

Intermediate coating

3㎜

2~3 times

Rake, Scraper, R

Black, Green, Gray

Information

Surface treatment

-

The most fundamental role of the surface treatment is to remove all foreign matter from the substrate, which could lead to early failure in the coating, and to clean the substrate so that the paint is adhered well to the substrate. The most important factor that determines the success or failure of the coating is the surface treatment. Since the adhesion between the paint and the substrate is reduced by foreign matter attached to the surface of the substrate, coating often becomes unsuccessful. For the surface treatment, there are mechanical and chemical methods. The mechanical method is generally used for the surface treatment in construction coating. The influence of the surface treatment on the coating effect is shown in the table below.

The parts made of cement accounts for the largest part of s building. Since the concrete and mortar contain moisture for a while after construction and also contain strong alkaline materials (pH12~13) and are gradually neutralized from the surface by carbon dioxide gas in the air during curing, care should be taken for moisture and alkali before coating. Concrete and mortar should be sufficiently cured before coating, and an abrasive should be sprayed (at least SSPC-SP7) to remove moisture (moisture content less than 6%, pH less than 9.5), oil and other foreign matter (release agent, laitance, etc.). However, the alkali component that is not easily neutralized migrates to the surface along with moisture remaining inside of the surface due to the shape or cracks of the structure and causes whitening, peeling and discoloration of the coating film. Therefore, the alkalinity should be loweredThe effect of each factor on the coating life upon coating

Factor Contribution rate (%) Surface treatment 50% Frequency of coating (difference between one and two coats) 20% Type of coating (difference between the same type of paints) 5% Others 25% ※ Others (coating environment, proficiency, etc.)

(1) Moisture

The substrate must be sufficiently dried to be coated. Generally, the drying time of cement material is not prescribed, but as follows.

Construction Time Summer Spring & autumn Winter Concrete 21 days 21~28 days 28 days Mortar 14 days 14~21 days 21 days (2) Alkali

It is usually maintained at a pH of 12 ~ 13 at the time of construction and gradually neutralized from the surface by carbon dioxide gas in the air during curing. However, the alkali component that is not easily neutralized migrates to the surface along with moisture remaining inside of the surface due to the shape or cracks of the structure and causes whitening, peeling and discoloration of the coating film. Usually, the alkalinity should be a pH of 9.5 or less to be coated.

(3) Condition of the substrate to be coated

Upon using the mold, the release agent, sand powder, and laitance are factors that hinder the adhesion of paint, thus the defective areas should be treated properly.

* Laitance: It is a weak concrete layer formed during coating on concrete as Ca(OH)₂ and CaCO₃ are present on the surface by the interaction of CaO in cement with water and carbon dioxide (CO₂).(4) Crack

Cracks caused by ambient temperature, humidity change, and other conditions should be filled in with the prescribed filler before coating. At this time, Noroo Seal 6600 epoxy putty should mainly be used.

(5) Concrete substrate adjustment

① Get rid of moisture from the dried and cured substrate and remove other debris or extraneous matter. ② For the prevention of absorption, coat with a water-based sealer or an epoxy sealer, etc. according to the type of coating material. ③ Fill the cracks and holes with cement, water-based caulking, putty, etc. ④ Polish the rough putty surface with sandpaper.

(6) Basics of concrete coating

① Investigate the quality of paints and become acquainted with how to use them. ② Arrange the substrate neatly and choose appropriate coating tools and equipment. ③ Use the paint after stirring it well. It is recommended to paint many thin coats instead of applying one thick coat. ④ Coat by avoiding dust, low-temperature, and high-humidity. ⑤ Avoid direct sunlight.

As for the coating object, for which surface treatment has been done, subsequent coating should be carried out as soon as possible. Particularly for steel, in order to prevent deterioration of the quality due to surface oxidation, the paint should be applied within 4 hours after the surface treatment in the case of blast surface treatment.

Coating method

-

Coating method

1. Preparation for Coating

Painting work should be carried out by complying with the technical data of the paint maker and other precautions. For multi paints, each paint should be sufficiently stirred and mixed according to the mixing ratio indicated in the product and technical data. If dilution is required, the specified thinner should be used. The dilution ratio can be adjusted according to the working conditions. Multi paints should be mixed beforehand, and the paints mixed with hardeners should be used within the pot life.

2. Coating Equipment and Coating Method

(1) Brush Coating

Even if the price of a roller or a brush is high, a good one should be purchased to make the work easier. The hair of a good brush is shiny, feels good, and does not bend well. Additionally, the tips of the hair are arranged neatly, and the waist of the brush has appropriate elasticity. For water-based paints, a brush with long and soft hair and for oil-based paints, and a brush with relatively less strong hair should be used.

① Select an appropriate brush according to the characteristics of the paint to be applied and the substrate to be coated. ② If a new brush is used, coat the brush with paint and rub it on a plank several times to neatly gather the brush ends to make brush dragging better before use. ③ Do not soak too much of the brush into the paint, but use after soaking about 60% of the brush into the paint. ④ Start to apply the paint required for a certain area properly. ⑤ Paint it evenly and widely after moderately applying the paint. ⑥ Finish smoothly so that brush marks do not remain. ⑦ As lacquer or quick-drying paint dries quickly, the motions in 4), 5), and 6) should be subsequently done almost at the same time.

(2) Roller Coating

When painting a large area such as ceilings or walls, the work speed of roller coating is faster than that of brush coating, and the paint can be applied evenly. Thus, even beginners can easily use it.

Moreover, it is convenient when painting ceilings or high walls because a long wooden bar handle can be attached freely.① Put the paint into the tray and wet the roller about 1/2 with the paint. Then, rub the roller several times on the tray plate to coat the cover hair with sufficient paint. ② Rub the roller on a flat surface, such as a veneer sheet, to soak the cover hair sufficiently with the paint. ③ Coat the roller uniformly with the paint by rubbing it on the tray plate after soaking it with the paint again and then start painting. ④ Lightly run the roller in a W-shape to distribute the paint evenly on the surface and spread the paint by overlapping the roller up and down. Then, run the roller in the same direction to remove the marks. ⑤ Since the roller cannot sufficiently reach the corners, it is better to coat the areas first with a brush and then the entire surface with the roller. ⑥ Since bubbles are likely to generate during roller coating, it is necessary to select a proper paint or thinner and adjust the viscosity.

(3) Air Spray Coating

This is a universal method to paint a large area. The air spray machine is simple and cheap, whereas the volume, pressure, and flow rate of the air must be appropriate to obtain a good film appearance. If air spray coating is not done properly, there will be a great loss of paint. Moreover, the paint will protrude from the surface of the object, thereby resulting in a poor appearance. In addition, if it is not operated properly, the coating surface will not be smooth, and the paint may run down, or pinholes may be formed in the coating film. In terms of air spray coating, the most unfavorable condition is that it cannot be applied thickly with one coat because it needs to be diluted with a solvent to adjust the viscosity of the paint.

① As spraying left and right is easier, always take the object to the place where spraying can be done easily or make it move to such a position by itself. ② On flat surfaces, spray the both ends on the left and right sides first and then proceed with spraying up and down. ③ When painting the ends, make sure that the center of the nozzle is aligned with the end line. ④ For large objects, start painting from the front and prevent dust from adhering to the back. ⑤ For angular objects, coat the angular parts first from a slightly closer distance and at a higher speed. ⑥ Prevent dust from settling into each part inside and apply in the same way as the flat surface. ⑦ For cylindrical objects, slowly apply up and down while rotating the object with a rotating platform. ⑧ For narrow objects, reduce the width of the pattern appropriate for the object. By doing so, coating will be finished neatly without wasting any paint. ⑨ For quick-drying paints such as lacquer, spray as continuously as possible. Otherwise, dust will settle on the dried surface, thereby resulting in a poor appearance.

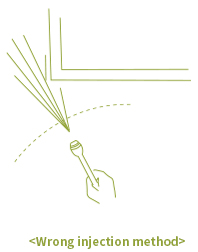

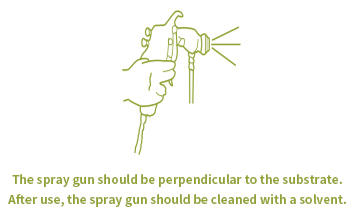

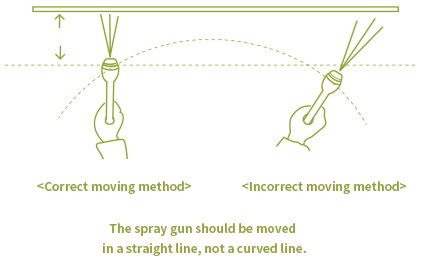

(4) Airless Spray Coating

In this method, air is not directly mixed into the paint to spray the paint. The ejection method is to eject the paint through a special nozzle or tip using pressure. The magnitude of the pressure used is calculated by comparing the ratio of the air pressure of the pump for the internal air pressure.

The pressure ratio of the pump is from 20:1 to 60:1, but a ratio of 30:1 is usually used. For zinc dust paints, especially inorganic zinc dust paints, a ratio of 45:1 should be used. Compared to air spray coating, some of the most important advantages is that there is a small loss of paint, toxicity can be reduced, and there is a low risk of explosion.

Also, since a small amount of solvent can be used upon injecting the paint, coating in a thick wet film thickness is possible. As already described, the ejection of the paint depends on the type of the tip that is specially designed. The tip or nozzle is made of tungsten carbide, and the amount of injection depends on the diameter of the nozzle. Therefore, there are many types of tips with various angles and different diameters. The selection of tip should be made based on the pressure according to the paint injection amount and on the diameter of the nozzle that maintains a constant ejection amount.

Namely, the speed at which the paint is ejected determines the film thickness of the paint. The angle of the tip is selected according to the width of the object to be coated. A tip with a nozzle diameter of 0.009″ to 0.013″ is suitable for coating approx. 50μ (2mils) of wet film. In addition, a tip with a nozzle diameter of 0.013″ to 0.019″ is suitable for 100~200μ (4~ 8mils), while a tip with a nozzle diameter of 0.019″ to 0.031″ is suitable for 200μ (8mils) or larger. For paints that should be applied very thickly, a tip with a nozzle diameter of 0.040″ to 0.060″ should be used.① For the airless sprayer, the spray pattern, shape, and paint injection amount are all determined by the nozzle tip. ② Maintain a proper injection distance. In general, 30㎝ is appropriate. If the distance is short, the coating becomes thick. Whereas, if the distance is far, uniform coating is difficult, and a large amount of paint is wasted. ③ The spray gun should be perpendicular to the substrate. ④ The spray gun should be moved in a straight line, not a curved line. ⑤ The moving speed of the spray gun should be about 40~80㎝ per second to obtain proper and uniform coating. ⑥ For the spray pattern, double coating at around 1/3 to 1/4 is suitable to obtain proper and uniform coating. ⑦ The pressure should be adjusted appropriately to obtain uniform coating. ⑧ The equipment should be cleaned with a specified cleaning agent immediately after use.

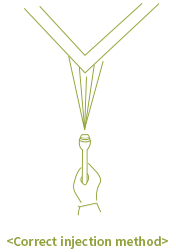

Proper Use Method of Coating Gun

3. Coating Conditions

(1) Temperature and Humidity

In general, the appropriate coating temperature range is between 10℃ and 30℃. It is advisable not to paint at temperatures below 5℃ or above 40℃.

If the surface temperature is high, the coating film may dry too quickly, thereby resulting in defects such as pinholes or blisters. In the case of low temperatures, not only slow curing, but also incomplete curing may be caused. To prevent surface condensation during coating, the temperature of the steel surface should be more than 3℃ above the dew point. When the humidity is high, the drying time is considerably delayed in the case of a paint that is generally dried by solvent evaporation. Particularly, coating should be avoided at a humidity of 85% or higher. In general, the optimum humidity range for coating is between 40% and 80%.(2) Others

Outdoor painting should be avoided on foggy, rainy or strong windy days.

In order to maximize the efficiency of work at the workplace, each employee should be familiar with the work of the workplace, and the special rules for the workplace described below must be followed.1) Keep the finishing material of the work in a place that can be protected from fire. 2) Always carry out the work safely. 3) In case of an accident, immediately call for first aid. 4) Modify and report what is considered unsafe. 5) Be aware of the heavy weight being applied when lifting or bending the knee. 6) An explosion-proof lamp and an enclosed switch should be used in the warehouse. 7) Product labeling should be appropriate and attached accurately. 8) Finishing materials should not be stored without an adequate cover in storage rooms. 9) Floors, walls, ceilings and painting rooms should be cleaned regularly. 10) Protective gear must be prepared and kept in good condition.

Theoretical Application Amount and Actual Application Amount

-

Theoretical Application Amount and Actual Application Amount

1. Theoretical Application Amount

In general, the recommended dry film thickness on the physical properties data sheet is presented based on a simulated ideal flat surface. The amount of application on the data sheet is also the theoretical application amount calculated based on it. The theoretical application amount is an amount that does not consider the surface condition to be coated, coating method, coating environment, and the amount of paint loss during coating. The theoretical application amount can be calculated simply by the following formula.

S (㎡/ℓ) = 10V/Tm

Here, S: Recommended Application Amount, meaning how many ㎡ can be coated with 1ℓ.

V: Solid Volume Ratio (%), meaning volume solid.

Tm: Recommended Dry Film Thickness (μ).

Example) What is the recommended application amount for a paint with a solid volume ratio of 55% to form a dry film thickness of 50?

<Explanation>

10×55/50 = 11.0(㎡/ℓ) The recommended application amount is 11.0㎡/ℓ.2. Actual Application Amount

Despite the manufacturer’s detailed data on the paint, it is very difficult to accurately calculate the amount of paint used in the actual site. Due to various factors in the actual site, more paint than the theoretical paint consumption is used. The difference between the theoretical paint consumption and the actual paint consumption is called loss, and when expressed as a percentage (%) is called loss rate.

1) Surface Roughness Coefficient

The amount of paint loss depends on the unevenness of the surface after the surface treatment, and the coefficient according to the unevenness of the surface is shown in the following table.

Surface Roughness Condition Primer Coating Coefficient Intermediate Coating or Top Coating Coefficient New smooth steel, picked steel 0.95 0.98 Blast cleaned steel 0.90 0.95 Power Tool cleaned 0.85 0.90 Blasted-lightly pitted steel 0.85 0.90 Blasted-heavily pitted steel 0.80 0.85 Rough concrete or Masonry 0.60 0.75 2) Coating Condition Coefficient

There are many differences in paint loss according to the coating equipment and other environmental conditions. The coefficient according to this is shown in the following tab

Coating Conditions Coefficient for All Coatings Brush or Roller 0.90 Spray-Interior 0.80 Spray-Exterior* 0.70 3) Actual Application Amount

Actual Application Amount

Actual Application Amount (㎡/ℓ) = Recommended Application Amount (㎡/ℓ) × Surface Roughness Coefficient × Coating Condition Coefficient4) Example

The undercoat with a solid volume ratio of 55% is intended to be coated with a dry film thickness of 50㎛. The surface treatment is blast (henvily pitted steel), the coating equipment is a spray, and the outdoor coating is done in an area without wind.

Here, What is the actual application amount?

① Recommended Application Amount = 10×55/50 = 11.0 (㎡/ℓ) ② Actual Application Amount = 11.0 × 0.8 × 0.7 = 6.2 (㎡/ℓ) ③ Loss rate = 11.0-6.2/50 × 100 = 43.6%